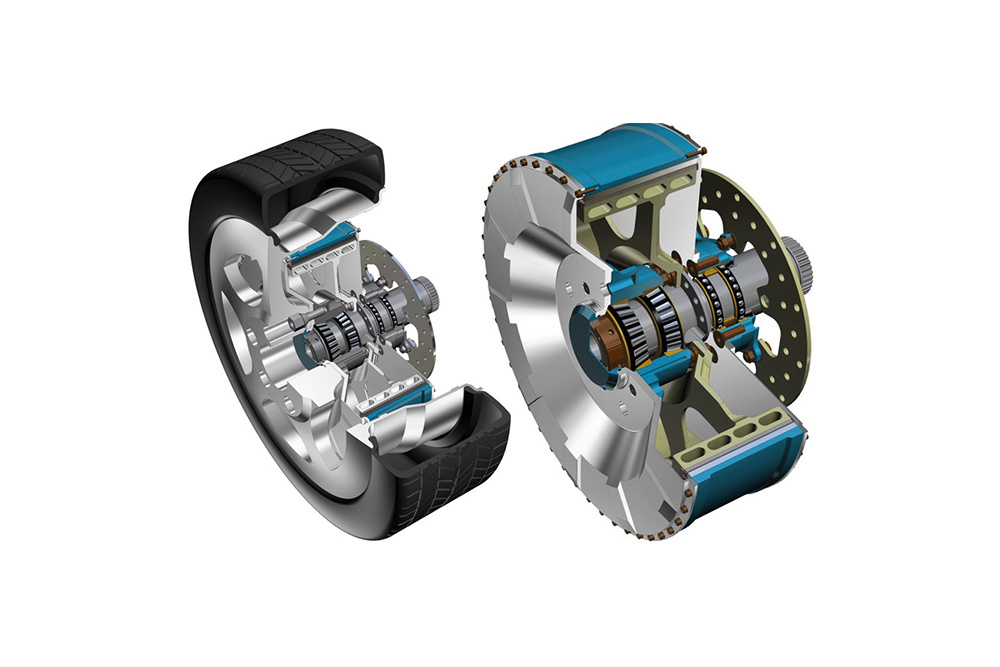

Drive System

The transmission system of an automobile consists of a clutch, a transmission, a universal joint, a final drive, a differential and a half shaft.

Product Type

Harmonic reducer is a new type of reducer transmission device, which consists of three basic components: rigid wheel, flexible wheel and wave generator. It has the characteristics of high speed ratio, small clearance, high precision, few parts, simple installation, high transmission efficiency and light weight.

The actuator module is an organic combination of the harmonic reducer, the motor that provides power, the drive board for the control system, the magnetic encoder, the brake pad and other parts. It has the characteristics of small size, light weight and easy installation. It is used in the joints of the shoulder, elbow, wrist and other joints of humanoid robots. It is also suitable for the joints of the mechanical arms of collaborative robots and industrial robots.

Second generation wheel hub bearing unit

Second-generation wheel hub bearing unit: combined with the first-generation wheel hub bearing, a hub flange is integrated to facilitate the flange installation of brake discs or steering knuckles.

Third generation wheel hub bearing unit

The third-generation wheel hub bearing consists of an outer ring with a flange connected to the suspension and an inner ring with a flange connected to the brake disc and rim. Some third-generation wheel hub bearings integrate ABS sensors.

First generation ball structure wheel hub bearing

The first-generation ball structure wheel hub bearing is a double-row angular contact ball bearing with an integral outer ring and a back-to-back combination of inner rings. It consists of an outer ring and two inner rings.

First generation tapered wheel hub bearing

The first-generation tapered structure wheel hub bearing is a double-row tapered roller bearing with an integral outer ring and a back-to-back combination of inner rings. It consists of an outer ring and two inner rings.

Heavy-duty truck bearings are mainly divided into: heavy-duty truck single-row tapered bearings or double-row tapered roller bearings, and second-generation products that partially integrate the flange connecting the suspension or the rim connecting flange.

Automotive bearings are composed of parts packages that provide value-added services to customers. The accessories package includes bolts, nuts, oil seals, snap rings and other accessories.

Metric single row tapered roller bearings

Single row tapered roller bearings, the bearing consists of an outer ring with a tapered raceway and a tapered inner ring, tapered rollers, etc. The inner ring assembly with rollers and cage can be installed separately from the outer ring.

British single row tapered roller bearings

Single row tapered roller bearings, the bearing consists of an outer ring with a tapered raceway and a tapered inner ring, tapered rollers, etc. The inner ring assembly with rollers and cage can be installed separately from the outer ring.

High-speed ball bearings are used in electric vehicle drive systems. The products need to be resistant to high speeds, high temperatures, and frequent starts and stops accompanied by impacts.

Through its axial movement, the clutch is separated, thereby cutting off the power transmission between the car engine and the transmission, and assisting the car in completing operations such as starting, shifting, and stopping. The release bearing can make the clutch system engage smoothly, separate gently, reduce wear, and extend the life of the clutch system. Clutch system service life.