Sling strength

Industry leading manufacturing and testing capabilities

We have perfect design analysis and experimental capabilities to optimize product design and parameters analysis on parameters ensure reliability of our products. In the production process, we realize integration of machining, assembly, testing and control. High-precision high-level and full-spectrum testing and experimental facilities provide a solid guarantee for our product quality.

1. International advanced production concepts

We are capable of pre-control and real-time analysis with product quality tracking management system covering the entire course of production,making our factories an integrated, fast responsive, elastic and lean informationized platform, and visualized, digital and smart modern factories.

2. Leading production and processing equipment

We are over thousands of domestic and international leading processing equipment and employ digital control technology to facilitate full process control, a solid hardware guarantee for us to offer products that truly satisfy our customers.

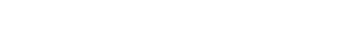

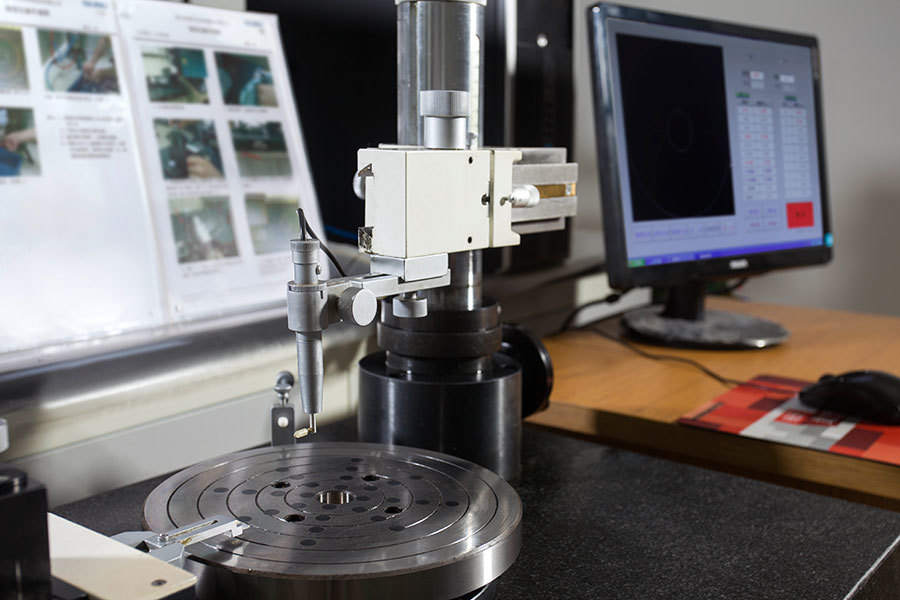

3. Full-spectrum quality inspection facilities

All kinds of high precision testing instruments are worked for the production field directly. It will control the whole production process in time and promise the size, shape, performance consistency and stability.

4. Complete laboratory center

The laboratory has passed the ISO/IEC17025: 2017 CNAS laboratory certification and obtained the certificate. It has the management level and testing ability recognized by the country and the world, and can provide objective, reliable and effective data.It has all kinds of testing machines required by the automobile bearing to simulate the actual situation of acceleration, steering, driving and impact of vehicles under various conditions such as wading, muddy road conditions, gravel splashing, minus 40 degrees below zero, and to test the various performances of wheel damaged bearings, and to verify and continuously promote the improvement of product quality with the test results.