Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Technical strength

Engineering technology

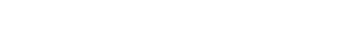

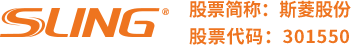

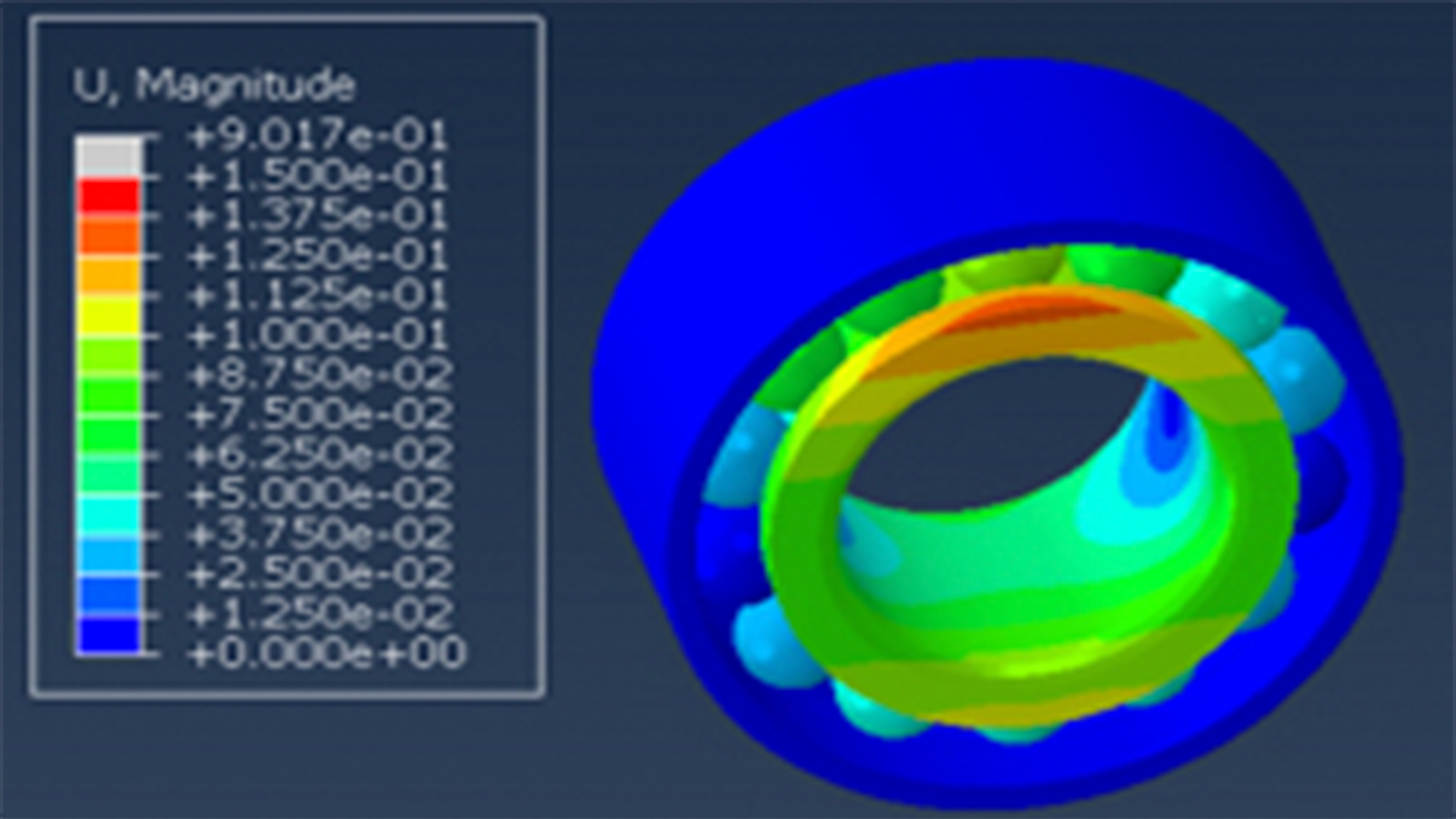

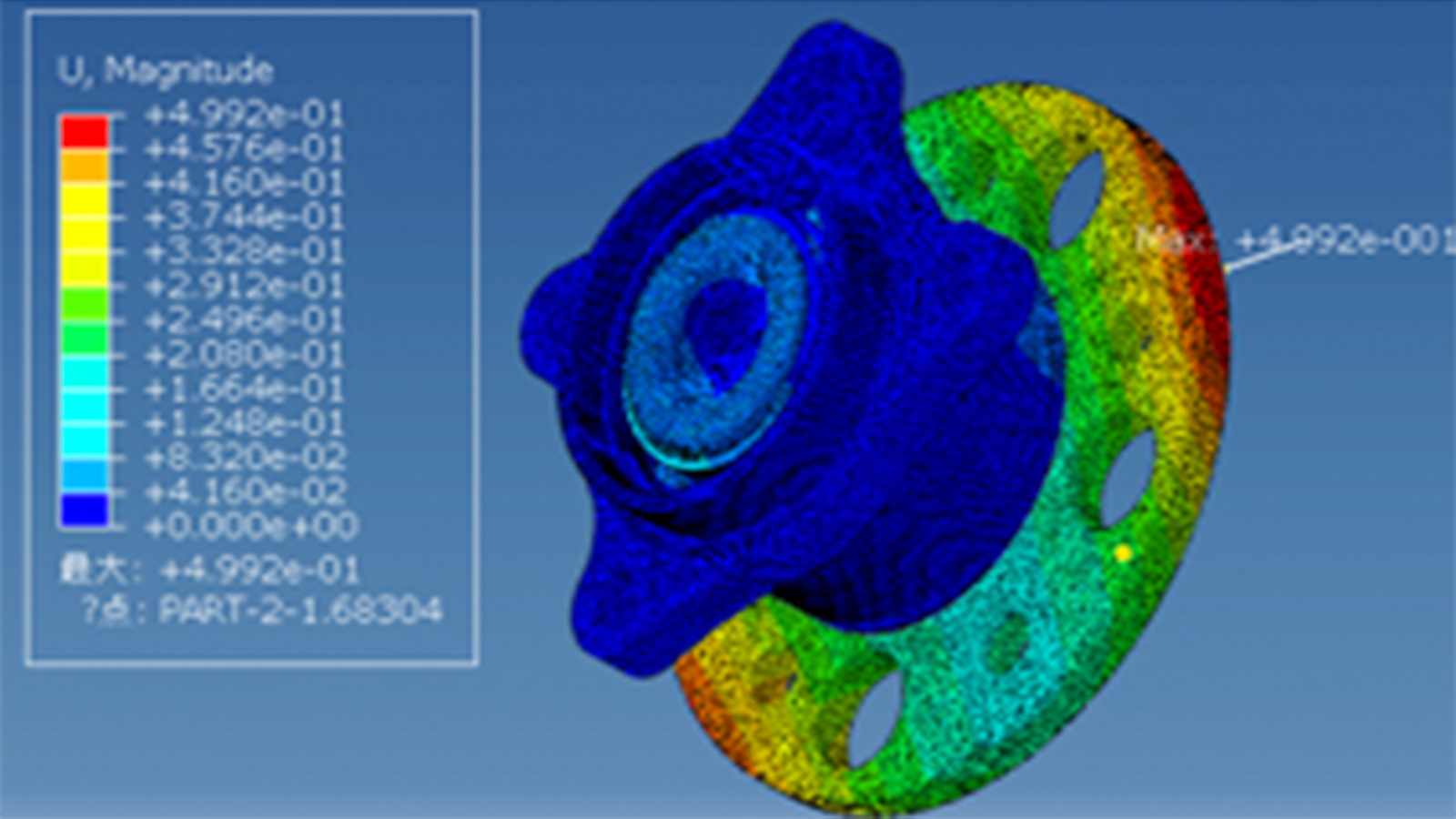

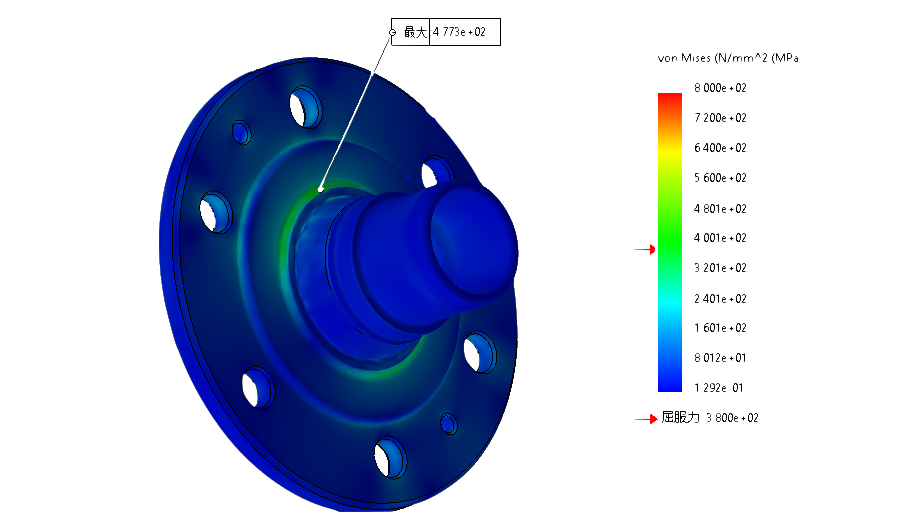

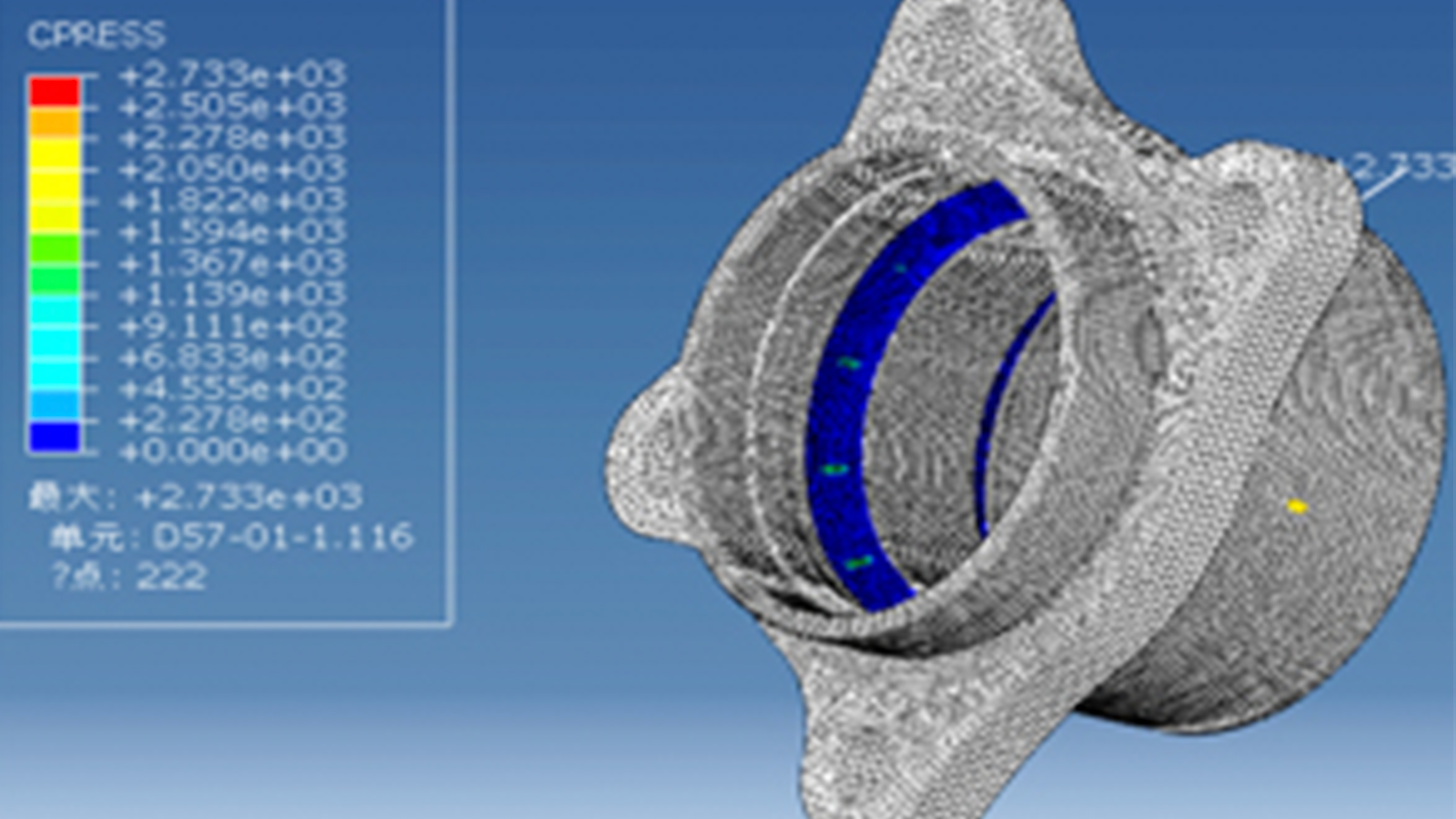

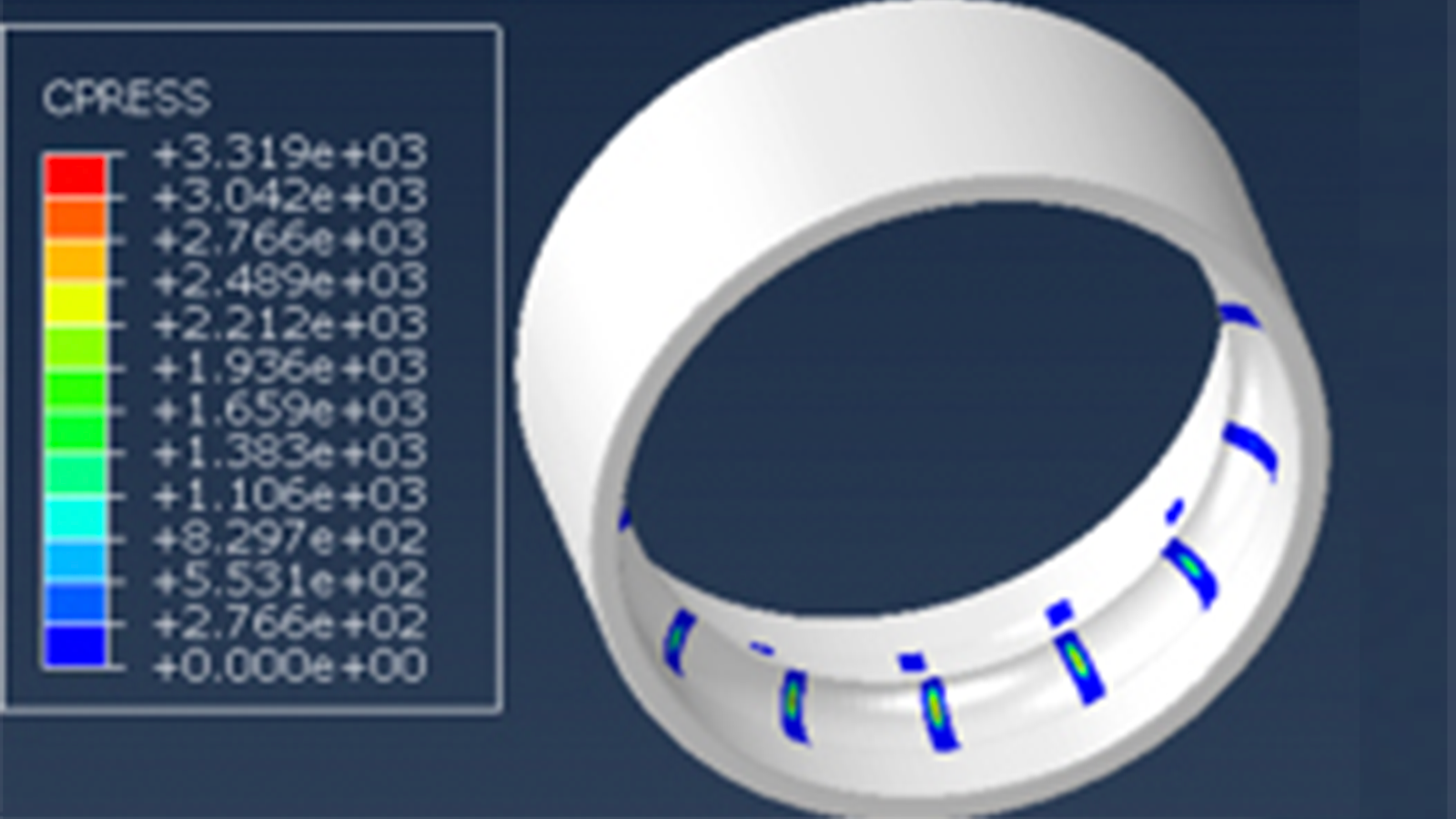

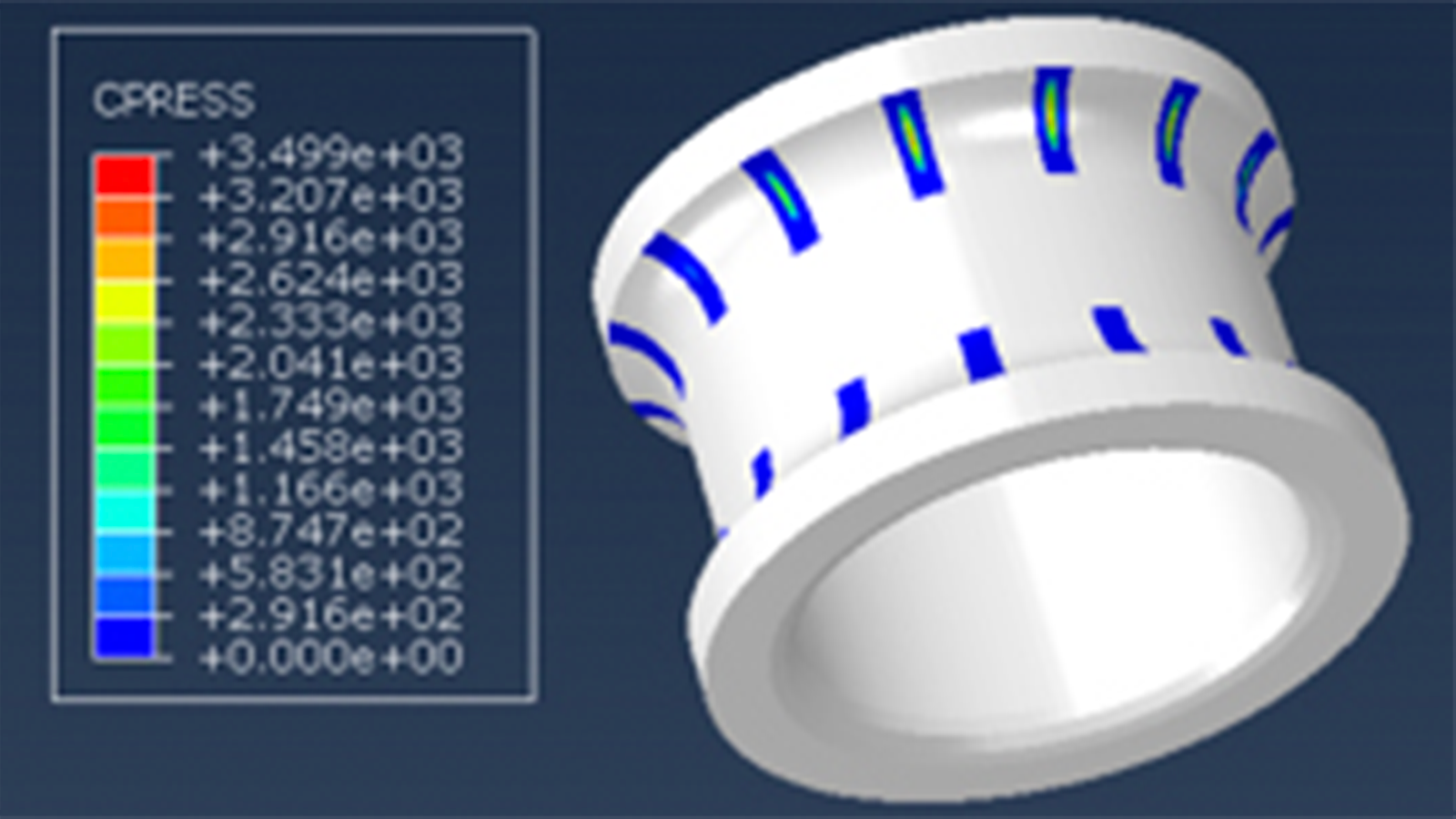

The company has the positive development experience of many brands and models, and has the synchronous development capability of OE products. In the product design and development stage, the maximum contact stress, stiffness and strength of the product are checked and analyzed through the application of ABAQUS, ANSYS and other CAE software in the remote computing cloud platform to optimize the product design and meet customer requirements. Provide customers with more value-added services in terms of lightweight and low torque.

WeChat Official Account

Copyright @ Zhejiang Siling Auto Bearing Co., Ltd. | Siling Collaborative Office System